Safety Considerations

While laser cleaning is often safer than traditional methods involving harsh chemicals or abrasive blasting, it is still a high-energy process that demands careful attention to safety. The laser itself is a concentrated beam of electromagnetic radiation capable of causing permanent eye and skin damage, while the ablation process can release microscopic particulates, toxic fumes, or high-decibel sound. Ensuring operator safety, process reliability, and regulatory compliance means taking a holistic approach to risk management—from equipment design to personal protective measures and environmental controls.

Laser Radiation Hazards

Laser cleaning systems—especially pulsed fiber and solid-state lasers—often operate at Class 4, the highest hazard level.

Direct and reflected beams can cause instantaneous eye injury, including retinal burns or permanent vision loss.

Diffuse reflections, especially off curved or reflective metal surfaces, can still pose risks at high power densities.

Safety Measures:

Use laser safety enclosures or barriers where possible.

Equip operators with certified laser safety goggles specific to the laser’s wavelength (e.g., 1064 nm for IR lasers).

Implement interlocks, emergency stops, and warning indicators on all equipment.

Particulate and Fume Generation

During laser ablation, contaminants are vaporized or broken into microscopic particles. Depending on the material, this can include:

Metal oxides, carbon particles, and polymer fumes

Toxic or carcinogenic byproducts, especially when cleaning lead-based paint, PVC, or radioactive surfaces

Safety Measures:

Use a high-efficiency extraction system (HEPA + activated carbon) to capture and filter airborne contaminants.

Follow NIOSH/OSHA guidelines for exposure limits.

In some cases, conduct air monitoring to ensure safe concentrations.

Thermal and Fire Hazards

Although laser cleaning is often described as “cool” or “non-thermal,” it can still ignite flammable materials or create localized hot spots.

Risk is elevated when cleaning resin-based coatings, greasy surfaces, or in confined spaces.

Sparks or small plasma flashes may occur during intense cleaning of rust, scale, or thick paint.

Safety Measures:

Keep fire extinguishers (Class A/B/C) nearby and train operators on emergency procedures.

Remove or isolate flammable materials from the work area.

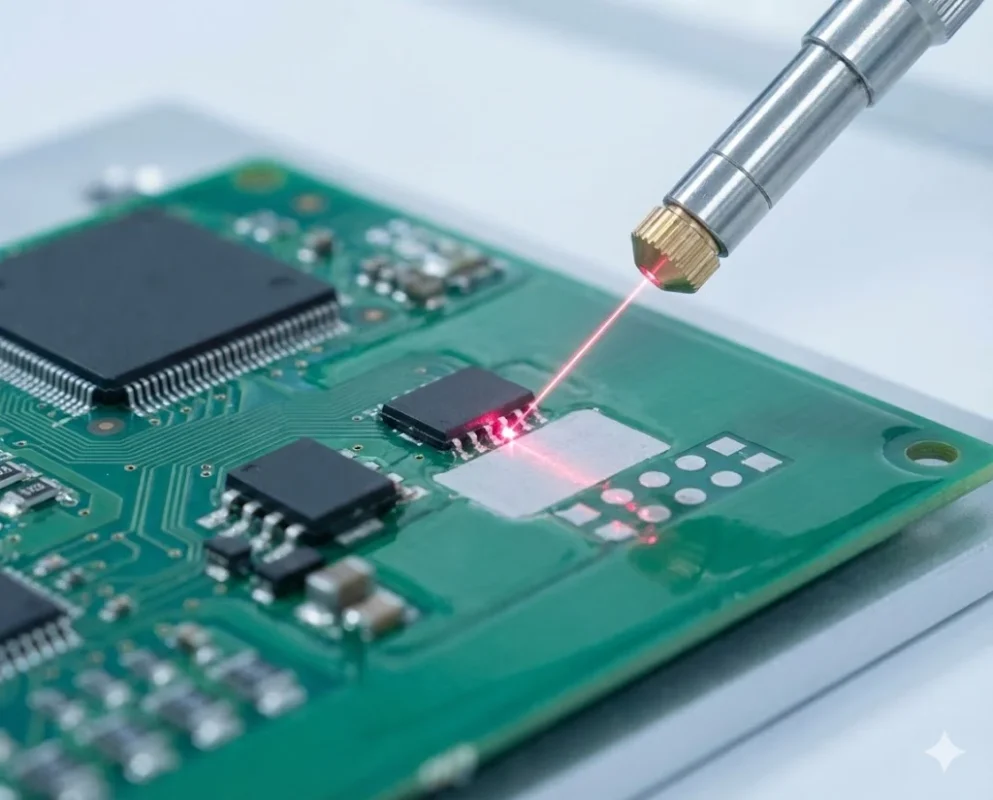

Use thermal shielding when working near sensitive components or electronics.

Acoustic Noise

Laser cleaning can generate ultrasonic pops, shockwaves, or high-frequency acoustic emissions, particularly in photo-mechanical cleaning at high pulse energies.

Noise levels may exceed 85 dB, requiring hearing protection.

Noise can vary based on the material, pulse rate, and contamination type.

Safety Measures:

Use hearing protection (earplugs or earmuffs) in high-noise environments.

Consider enclosure systems with sound-dampening materials.

Electrical and Mechanical Safety

Laser cleaning systems integrate high-voltage power supplies, motion control, and scanning heads, which introduce electrical and mechanical risks.

Electrical faults, especially in poorly grounded systems, can be dangerous.

Mechanical hazards may arise from automated gantries, robotic arms, or moving optics.

Safety Measures:

Follow lockout/tagout procedures during maintenance.

Ensure all equipment is properly grounded and regularly inspected.

Implement motion safety zones and restrict unauthorized access during operation.

Training and Operational Discipline

Even with advanced equipment, the most effective safety system is a well-trained operator.

Training should include laser physics, equipment handling, emergency procedures, and PPE usage.

Maintain standard operating procedures (SOPs) and safety checklists.

Conduct regular safety audits and drills to reinforce good practices.

Laser cleaning is inherently cleaner and safer than many conventional processes, but it introduces unique hazards that must be actively managed. These include: Laser radiation exposure, toxic particulate release, thermal and fire risk, and acoustic and mechanical dangers.

With proper system design, air filtration, operator protection, and training, these risks can be fully controlled, making laser cleaning not only a precise and eco-friendly solution but also a safe and sustainable technology for industrial, heritage, and high-tech applications.

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us