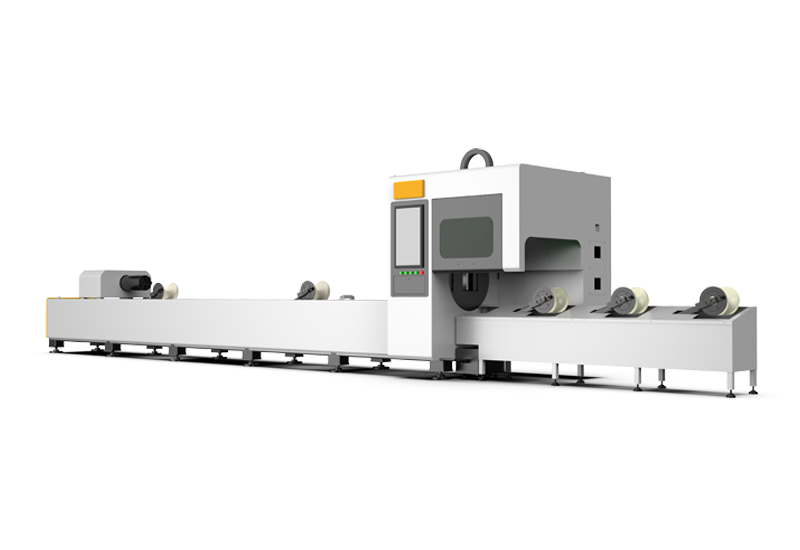

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Tube Laser Cutting Machine

Sheet Metal Laser Cutting Machine

Sheet & Tube Laser Cutting Machine

Medium Power Metal Laser Cutting Machine

High Power Fiber Laser Cutting Machine

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us