Choosing the right fiber laser cutting machine is an important investment decision for metal fabrication companies. The correct configuration can significantly improve cutting efficiency, reduce operating costs, and support long-term production growth. This guide explains the key factors you should evaluate before purchasing a fiber laser cutter, especially if this is your first time buying industrial laser equipment.

1. Material Type and Cutting Thickness

The first step is to clearly define the materials you plan to process and their maximum thickness. Fiber laser cutting machines are widely used for carbon steel, stainless steel, aluminum, brass, and copper, but required laser power varies greatly depending on material type and thickness.

For example, cutting 1–3 mm stainless steel does not require extremely high power, while cutting 20 mm or thicker carbon steel will demand a much stronger laser source. Selecting power based only on maximum thickness is risky; a reasonable power margin helps maintain stable cutting speed and edge quality in daily production.

2. Laser Power (kW) and Cutting Speed

Laser power directly affects cutting speed, efficiency, and processing range. Higher power allows faster cutting and better performance on thick plates, but it also increases equipment cost and energy consumption.

Instead of blindly choosing the highest power, buyers should match laser power with real production needs. In many workshops, a properly configured mid-power fiber laser can outperform an oversized machine in terms of overall return on investment.

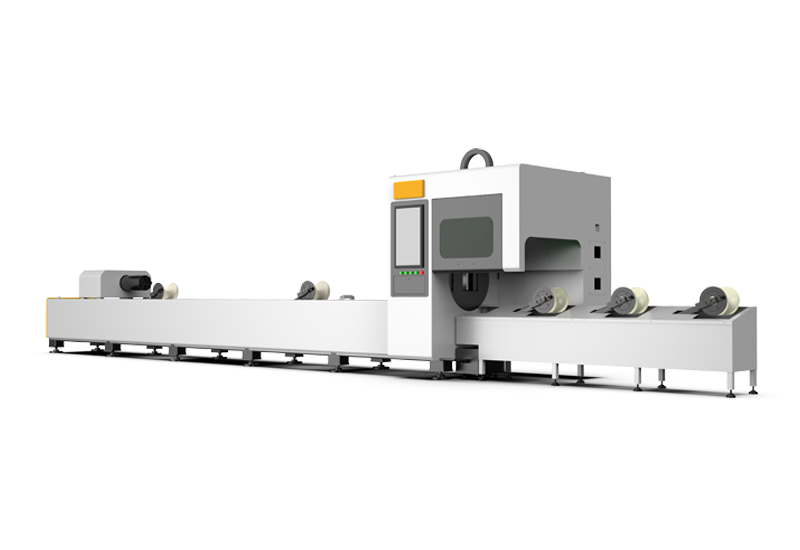

3. Cutting Area and Machine Type

Another key decision is whether you need to process sheets, tubes, or both. Standard flatbed fiber laser cutting machines are designed for sheet metal, while tube laser cutting machines specialize in round, square, and rectangular pipes.

Some manufacturers offer combined sheet-and-tube models, which provide flexibility for small to medium workshops. However, for high-volume production, dedicated machines often deliver higher efficiency and better long-term stability.

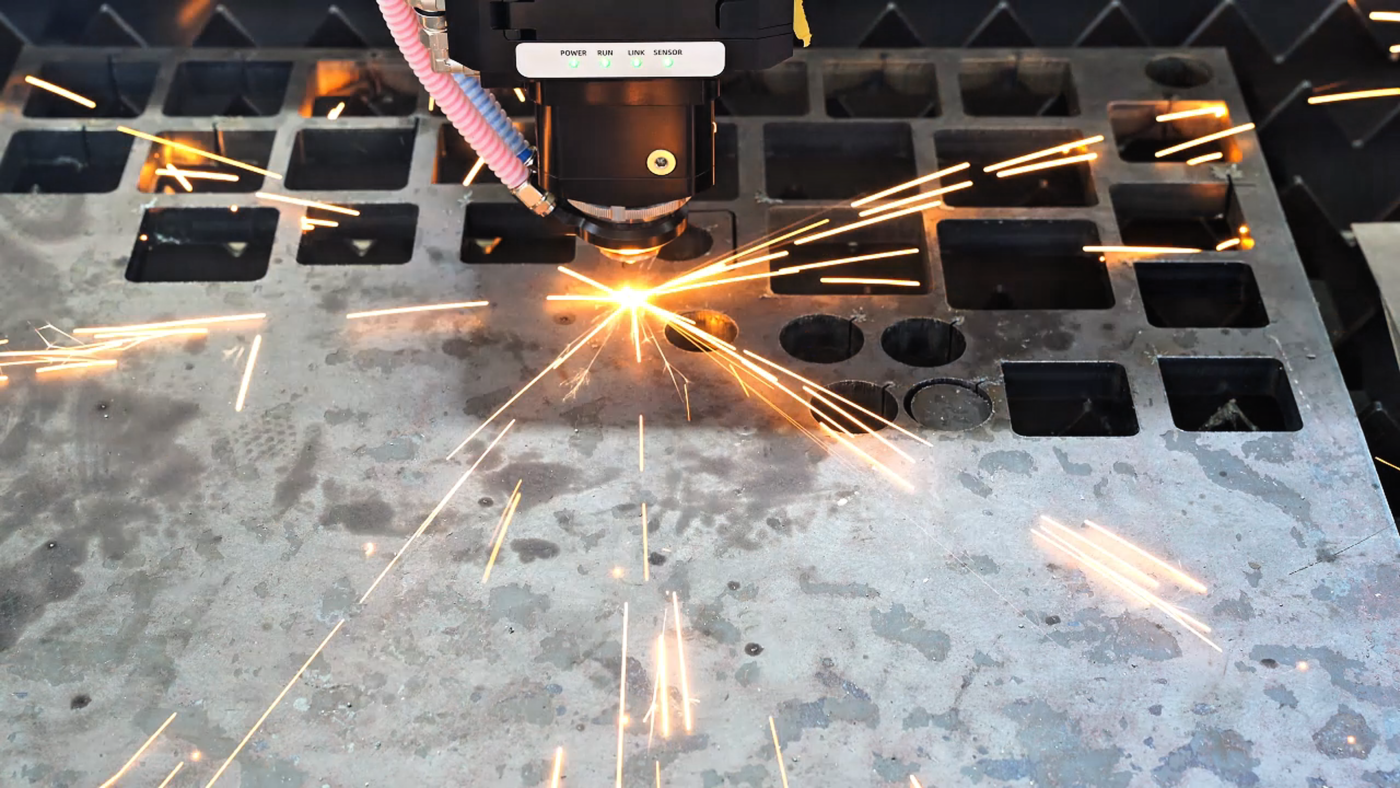

4. Accuracy, Precision, and Key Components

Cutting accuracy depends not only on laser power but also on core components such as the laser source, cutting head, servo motors, guide rails, and control system. High-quality components ensure stable motion, smooth corners, and consistent repeatability over long operating hours.

When comparing machines, buyers should look beyond basic specifications and pay attention to component brands, assembly quality, and machine rigidity.

5. Build Quality and Structural Stability

A rigid machine frame plays a crucial role in long-term performance. A well-designed bed and gantry structure reduces vibration during high-speed cutting, improves accuracy, and extends the service life of key mechanical parts.

Poor structural stability may not be obvious during short-term testing but often leads to accuracy loss and higher maintenance costs after extended use.

6. Software and Ease of Operation

User-friendly software simplifies daily operation, reduces training time, and minimizes human error. Compatibility with common CAD/CAM systems allows smoother file transfer and faster job setup.

Modern fiber laser cutting machines often include intelligent nesting, automatic parameter optimization, and real-time monitoring, which help improve productivity and material utilization.

7. After-Sales Support and Service Reliability

After-sales service is one of the most underestimated factors when purchasing a laser cutting machine. Installation guidance, operator training, spare parts availability, and technical support all directly affect machine uptime.

Choosing a manufacturer with proven service experience and long-term customer references reduces operational risk, especially for overseas buyers.

8. Cost, Efficiency, and Return on Investment

The initial purchase price is only part of the total cost. Energy consumption, maintenance, consumables, and productivity all influence long-term operating expenses. A machine with higher efficiency and stable performance often delivers better ROI even if the upfront cost is slightly higher.

Buyers should evaluate equipment from a long-term operational perspective rather than focusing solely on price.

0531-87978823

0531-87978823 +86 16653132325

+86 16653132325 sales01@raytu.com

sales01@raytu.com Contact us

Contact us